01732 759725

24

MPS

The circular economy is fast gaining

ground as the latest buzzword in

sustainability, bringing together

emerging practices, such as

collaborative consumption, and

traditional concepts like recycling

and remanufacturing. The circular

economy aims to eradicate waste by

departing from the linear ‘take, make

and dispose’ model and its reliance

on infinite natural resources and

energy. According to McKinsey, each

year around 80% of the $3.2 trillion

worth of materials used in consumer

goods are not recovered

1

.

Through a more effective use of

materials, the circular economy envisions

a smarter approach to the creation, use

and disposal/recycling of products. As well

as the obvious environmental benefits,

the transition to a circular economy will

be driven by the promise of over $1tn

in business opportunities, according

to estimates by the Ellen MacArthur

Foundation

2

. This includes material savings,

increased productivity, new jobs and new

categories of product and business.

International momentum

Some countries are already starting to

introduce legislative drivers such as waste

prevention targets and incentives around

eco-design to promote products that

are easier to reuse, remanufacture and

disassemble.

China has set up CACE, a government-

backed association to encourage circular

growth, while Scotland has issued its own

circular economy blueprint. In a significant

move, the European Commission’s circular

economy framework, to be released in

late 2015, is expected to introduce higher

recycling targets and a landfill ban on

recyclable materials across all 28 EU

member states.

According to weight-based material

flow analysis conducted in 2010 by the

Waste & Resources Action Programme

(WRAP)

3

,19% of the UK economy is

already operating in a circular fashion.

This relates to the weight of domestic

material input entering the economy (600

million tonnes), compared to the amount

of material recycled (115 million tonnes).

WRAP predicts this figure could rise to

nearly 27% by 2020, assuming 137 million

tonnes of material is recycled from a direct

material input of 510 million tonnes.

Services innovation

The circular economy is also enabling

some companies to think differently.

Whereas previously profits may have been

created by getting customers to buy new

equipment on a regular basis, in the future

taxes and other costs – such as those

forced on companies through the European

Waste Electrical and Electronic Equipment

(WEEE) regulations – may encourage more

design for longevity backed with a more

service-oriented profit line.

Our relationship with the products

and services we purchase could change

dramatically under a circular economy,

from ownership to favouring access and

performance. By selling the benefits

of products as part of an overall

solution, instead of the actual products,

manufacturers begin to design against

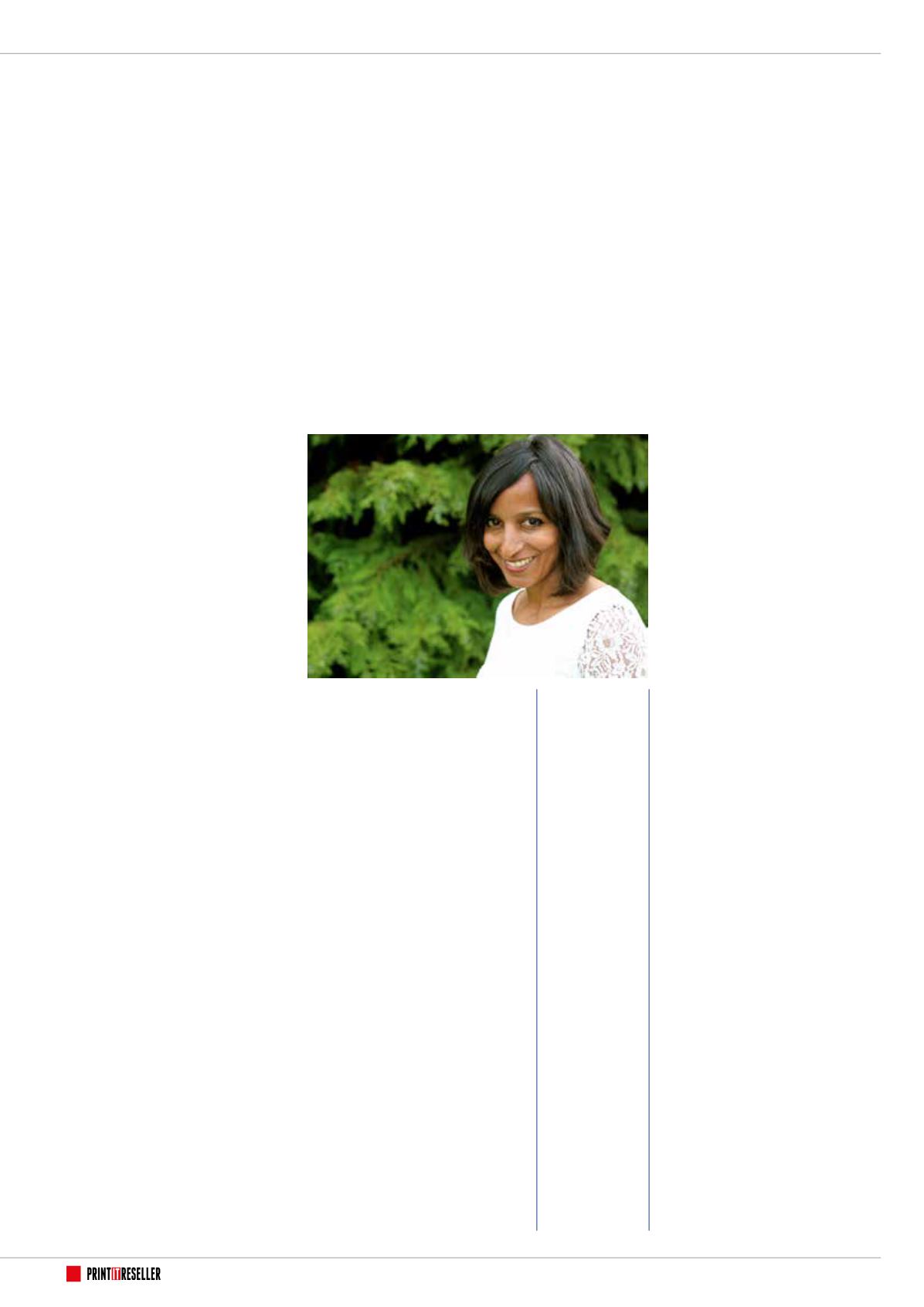

As WRAP launches a new report suggesting that expansion of the

circular economy could create three million extra jobs in Europe by 2030,

Quocirca’s Louella Fernandes explains how MPS can help reduce waste

Rethinking MPS for

the Circular Economy

different criteria, monetising product

longevity through service, upgrade and

remanufacturing.

Some product categories are more

likely to benefit from being a service-based

proposition than others. A recent

Guardian

survey found a majority of business owners

(66%) felt technology hardware/equipment

offered most value as a product-service

model, followed by electronic and electrical

equipment (56%) and cars, tyres and parts

(51%)

4

.

Indeed, smart, connected products

are expected to transform the next

wave of manufacturing. Self-monitoring

enables remote control, optimisation and

automation and the tracking of a product’s

operating characteristics and history to

better understand product usage. This

data has important implications for both

product design and after-sales service –

enabling proactive and automated service

and maintenance.

This approach facilitates a shift to

usage-based models, offering the potential

to extend the ‘pay per use’ contracts

associated with smartphones to other

products, such as washing machines or

even clothes. Already, Philips, a strong

advocate of the circular economy, sells

lighting as a service to its business

customers. Customers only pay for the light

and Philips takes care of the technology

risk and investment. It can also take the

equipment back to recycle the materials or

upgrade them for reuse.

The next frontier for printer

manufacturers

The circular economy approach is nothing

new in the print industry, which has long

been striving to enhance its sustainability

credentials. This includes the manufacturing

process, the responsible recycling of ink

and toner and the provision of hardware,

software and services that eliminate

wasteful paper and energy usage.

From a manufacturer perspective,

many are already designing and building

products that are part of a value network

where reuse and refurbishment at a

product, component and material level

assures continuous re-use of resources.

Some

countries

are already

starting to

introduce

legislative

drivers such

as waste

prevention

targets and

inventives

around eco-

design

Louella Fernandes,

Quocirca