01732 759725

SUPPLY CHAIN

32

I can’t recall

more than a

handful of

errors in the

last ten to

fifteen years

...continued.

Howe said. “Order confirmation and billing

comes from Manchester and we allocate

the mode of transportation for every order

before we send them to DHL, whether it’s

by courier, haulier, trailer, or even first or

second class post,” he added.

Howe recently switched carriers,

appointing DPD as it sends text messages

to advise customers of a one-hour delivery

window. “That’s an extra value-add service

that our customers can enjoy,” he said.

Some customers have their own

warehousing and have specific logistics

requirements that Brother needs to meet.

“We can send out ten to twelve trailers a

week to some distributors, each of these

will hold products with different labels

and will be packed in pallets that meet

individual customers’ specifications in

terms of height, size and volume. And the

requirements can vary enormously, some

customers with multiple locations have

different requests depending on which

site the order is to be delivered to. We’re

responsible for all of that detail,” he

added.

According to Howe the logistics

operation has to constantly flex and

change. “Customers can transact with us

any way they wish, from email or via file

transfer. We’ve built lots of flexible systems

and we are continuously reshaping how

we work,” he said, citing MPS as one

example. “The market is moving and MPS

deployments becoming more mainstream,

Brother’s MPS model is scalable from a

basic offer to a more sophisticated solution

and we’re rolling it out through the

channel.

“There are any number of challenges

that come with that. Once a dealer has

set-up an MPS contract we manage the

supplies replenishment on their behalf

and ship the consumables to wherever an

individual device is located,” he added.

He continued: “Each customer has

different requirements and we have to

ensure that we’re set-up to meet all of

their needs. Whether that’s to deploy

a trailer to fulfil an order placed by a

distributor, ship a delivery to a large retailer

who needs a bespoke service, despatch

one device to a reseller, or send a set of

consumables to a dealer’s MPS contract

customer.”

Customer service

The operation is slick. “A trailer could be

carrying 150 SKUs but if a query is logged

we can tell the customer which box an

individual item is packed in. That’s how

we add value to our customers. There’s no

product crossover, no shortages and I can’t

recall more than a handful of errors in the

last ten to fifteen years,” he said. “There

might be the odd tape or cartridge that’s

damaged or gets lost, but that’s about it.”

He continued: “That’s the high level

of service we offer. Our customers don’t

have to worry about whether or not their

goods will arrive on time, or if there will be

products missing or damaged. We do extra

things that mean they don’t have to quality

check onsite. They know it’s right and that

reassurance can take cost and waste out of

their operations.”

All returns are received in Manchester

which houses a workshop staffed by eight

highly skilled engineers. “Customer repairs

are done onsite, we pull all spare parts

from Germany and wherever possible

we aim to offer customers a 48-hour

turnaround,” Howe said.

Brother employs a further four field-

based service engineers who in addition to

repairing devices at customers’ own sites,

also train dealers and other third-party

service providers to maintain and repair

Brother printers.

The company has a first level customer

contact centre in Kingston upon Thames as

well as a second level call centre at head

office. “We’re constantly training our first

level operators which reduces the volume

of calls that get escalated, in turn this

helps us continue to improve and evolve

our second level support teams,” Howe

said.

Running a tight ship

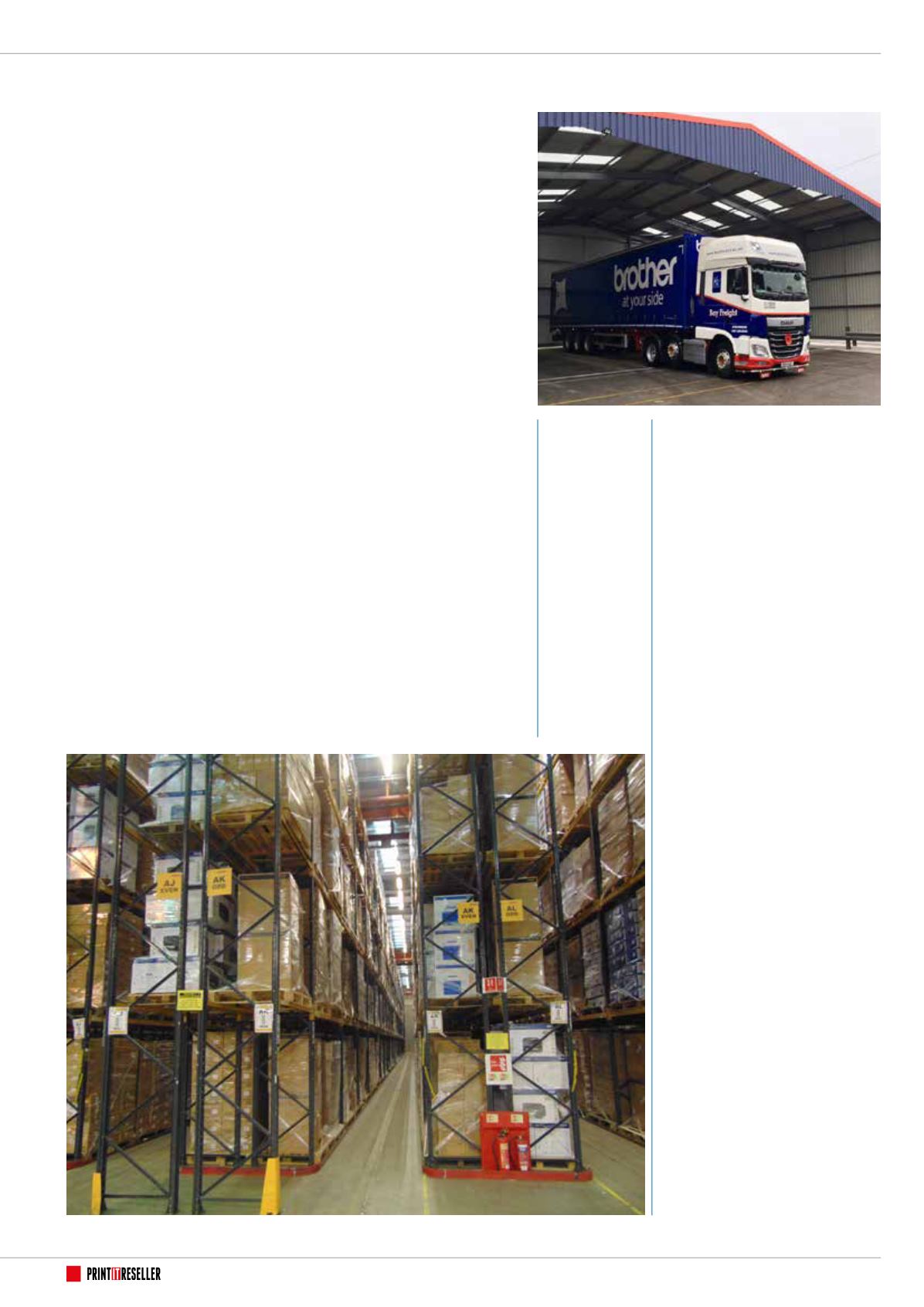

Inventory control is a smooth operation

at Brother and Howe runs a tight ship.

“In association with Deloitte we do

an inventory count twice a year,” he

explained.

The last inventory took place in October

last year. Howe confirmed that there

was no loss on units but there was one

difference in value. “We had a crossover

on one product which resulted in the small

valuation charge,” he explained. “Our

variance on loss was just £500 for the year

and that’s on a stock holding worth £140

million. That’s something we’re incredibly

proud of,” he added.

Recording such a small loss is no mean

feat when you consider that during this

financial year, Brother delivered 4.3 million

items and the total number of claims

agreed was just six.