01732 759725

28

SUPPLY CHAIN

Howe is based in Brother’s head

office in Manchester and has overall

responsibility for procurement,

import/customs, storage and

warehousing, as well as co-ordinating

and planning all of the deliveries to

the company’s channel customers.

You only have to travel a short distance

before you see any number of lorries,

HGVs and delivery trucks on the roads,

but I for one haven’t really given much

thought to how the products we buy for

work and for home, get from A to B. Howe

explained what happens behind the scenes

at Brother and how its supply chain and

logistics infrastructure is geared to provide

a seamless, flexible service to its customer

base.

Two months ahead

Brother printers and consumables are

manufactured worldwide, the company

has ten sites in Japan and its products are

also produced in other facilities in China,

Vietnam, Eastern Europe, USA, Philippines,

Malaysia and the UK. With shipping

typically taking several weeks, forward

planning is essential and orders are placed

well in advance to ensure sufficient stock

is onsite to fulfil customer orders. “We

are always two months ahead of what

we need to do from a purchasing point of

view,” Howe explained.

“We also need to take other factors

that impact on lead times into account, for

example, Chinese New Year means that

we can’t place orders in December, so we

need to bring these forward a month or so

to ensure that stock is received in January.

At any one time we could have between

£8 to £9 million worth of stock in transit,”

he added.

Brother also has a strong presence

across Europe which includes a central

stockholding facility in France and a

warehouse for spare parts in Germany.

“We replenish certain lines from France

once a week and deliver these directly onto

our customers,” Howe said.

Recovery planning is also part and

parcel of the job. “We have to work on

worst case scenario and have a plan B

in place if we’re unable to source from

the Far East, or if there’s likely to be any

delay with the shipping for example,” he

Some 4.3 million Brother products are delivered to customers across the UK each year.

PrintIT Reseller

caught up with Keith Howe, Director of Supply Chain and Service,

to find out more about the company’s supply chain and logistics infrastructure

Logistics in action

said. “If we need to, we can pull products

in from Europe and vice versa. We have

almost instant access to around six weeks’

inventory, we might need to rework the

instruction manuals for example, but

having that flexibility is tightly embedded

into the planning process,” he added.

Working the logistics

Howe heads up a 50+strong in-house

team of logistics and service personnel.

He also manages and oversees the

company’s outsourced services that

includes local storage and warehousing

facilities as well as a large distribution

facility in Lutterworth, third-party delivery

companies, the service division and the

customer service call centres.

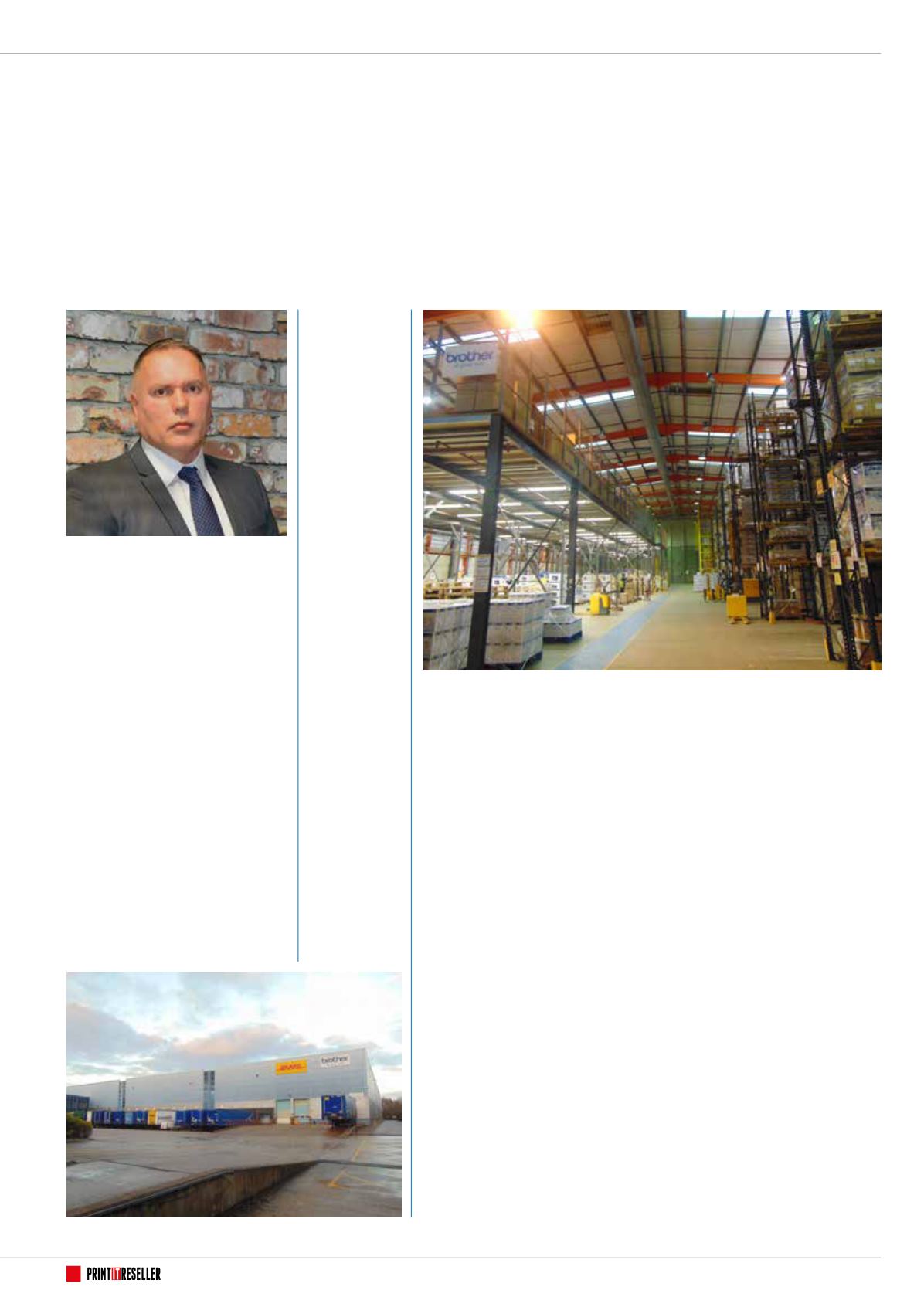

The Lutterworth-based warehouse

and distribution centre typically houses

between 10,000 to 12,000 pallets at any

one time. “That’s our basic stockholding,”

Howe explained. All distributor and dealer

orders are managed and co-ordinated

from our head office and the brief for the

transportation of each and every order is

led by Howe and his team.

“Whilst we use a third-party site, it

runs as if it was a Brother owned site,”

Brother also

has a strong

presence

across

Europe which

includes a

central stock

holding

facility in

France and

a warehouse

for spare

parts in

Germany

continued on page 32...

Keith Howe,

Director of Supply

Chain and Service,

Brother