01732 759725

DISTRIBUTION

32

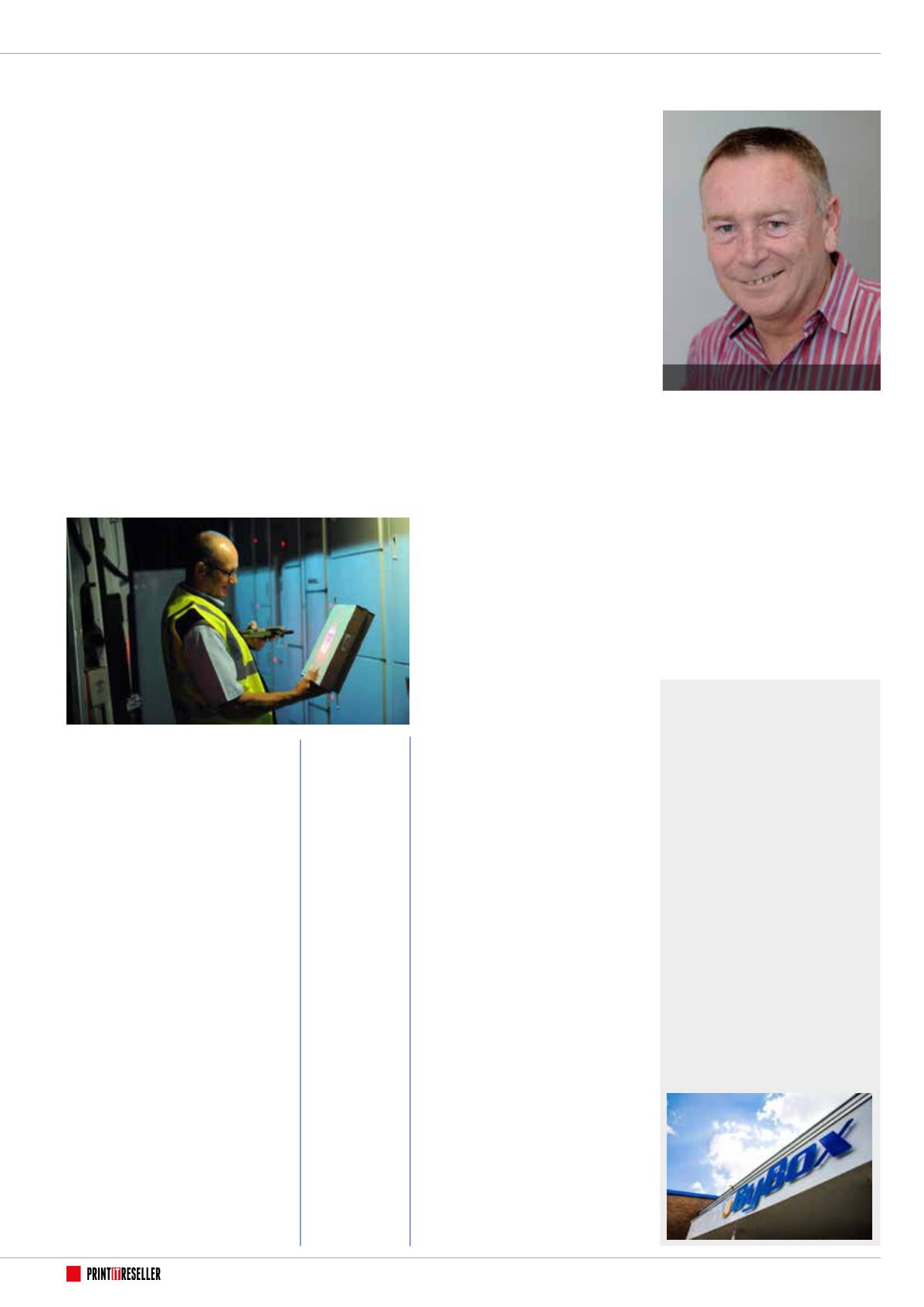

Founded in 2000, ByBox started

a revolution in field services by

delivering parts and tools overnight

to a network of lockers for engineers

to pick up in the morning. Today, its

locker network comprises over 1,800

locations nationwide.

Managing Director Mark Garritt says

that ByBox’s network has significant

benefits for the printer industry.

“An outsider looking in might think

the set-up (in the printer channel) is

convoluted, with dealers and distributors

sitting between the OEMs and end

customers. But those on the inside – the

vendors, buyers and dealers – appreciate

the added benefits that this supply chain

provides, especially in instances where

OEMs have a centralised European

warehouse model,” he said.

For such a model to work – and for the

channel to provide the service levels end

users expect – Garritt says it is vital for

engineers and dealers to be able to source

the parts they need without delay.

“In today’s digitised world, providing

strong support services to keep equipment

up and running should be one of the

main priorities for all involved in the print

industry. After all, dealers need to ensure

that their service is up to scratch, not just

to keep those who buy from them happy,

but also to ensure good relationships with

their product providers. In order to do

this, the easiest method is to construct an

all-in-one engineering and delivery supply

chain,” he said.

This is just what ByBox makes possible.

Its technology runs throughout the entire

supply chain, from delivery planning through

to locker design, to ensure that stock and

replacement parts are distributed from

OEMs to customers as efficiently as possible.

“Typical distribution networks require

large amounts of warehousing on the part

of the OEM, covering all the parts that may

be required at one time, and also have

inefficient delivery systems to customers

and engineers, as parts are dropped off

one-by-one. Yet new technology is helping

to streamline this model. New software

that can locate a specific piece of inventory

in any part of the supply chain means that

OEMs no longer need to have such large-

scale storage operations,” Garritt explained.

Instead, parts and equipment can be

held either by the distributor or the OEM

and automatically routed through the

network to wherever they are required,

reducing turnaround times and negating

the need for large stockpiles.

Delivery has been improved, too, with

locker technology replacing the ‘classic’

model that requires engineers to drive to a

warehouse to pick up inventory and then

go direct to the recipient.

“Locker pick up points improve

efficiency by the simple virtue of location,”

said Garritt. “They are closer to the

engineers, thus reducing the time spent

travelling. They also provide set delivery

locations rather than a plethora of

individual drop-off points, reducing the

time and fuel used in getting parts to

engineers. These two simple factors allow a

dealer to sell to a wider area, as engineers

are less constrained by their pick-up and

drop-off locations, saving costs while also

opening up avenues for new business.”

As ByBox opens a new local distribution centre

in Coventry (see box), managing director Mark

Garritt explains how the company has brought

greater efficiency to the printer channel.

Revolutionising

the print channel,

one supply chain

at a time

Garritt says that such a multi-faceted

supply chain should be high on the list of

any dealer looking to develop its services

in today’s highly competitive environment.

“Digital requirements are only going

to increase, so dealers will naturally be

competing with each other to ensure

their service is the pick of the bunch. The

back room logistics behind the business

should be the first area to be looked

at, as developing and modernising this

can revolutionise the service provided,

helping to retain customers, build OEM

relationships and create a rock-solid

enterprise,” he said.

...it is vital

for engineers

and dealers

to be able to

source the

parts they

need without

delay.

ByBox opens

new Coventry

distribution

centre

ByBox has opened a new local

distribution centre in Coventry to

increase capacity and support the

company’s record growth over the

past six months.

The facility in Rowley Drive, Coventry

is being used as a local distribution

centre and maintenance hub, processing

deliveries and returns going through the

supply chain.

The Coventry site is in addition to

existing ByBox distribution centres in

Milton Keynes, Belfast, Bristol, Glasgow,

Haydock, Thetford, London, Newcastle

and Doncaster.

Mark Garritt, Managing Director, ByBox